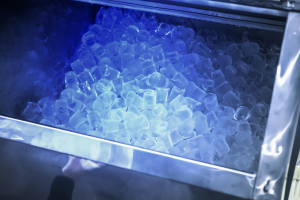

The smooth operation of a commercial ice machine is crucial to daily business. A well-functioning ice machine ensures that beverages are served perfectly chilled, contributing significantly to customer satisfaction.

However, like any other piece of commercial kitchen equipment, ice machines require regular maintenance to operate efficiently. Proper commercial ice machine maintenance can extend the lifespan of your equipment, ensure the production of high-quality ice, and minimize the likelihood of costly repairs and operational downtimes.

Here are some expert tips and best practices for keeping your commercial ice machine running smoothly.

Regular Cleaning and Sanitizing

1. Scheduled Cleaning

It’s essential to establish a regular cleaning schedule for your ice machine. Manufacturers typically recommend cleaning and sanitizing the machine every six months, but this can vary depending on the usage volume and environmental conditions. High-traffic locations or areas with hard water may require more frequent cleaning.

2. Sanitizing Components

Ensure that all parts of the machine that come into contact with water or ice are thoroughly sanitized. This includes the water filter, storage bin, and dispenser. Use a solution recommended by the ice machine manufacturer to avoid damaging sensitive components.

Water Filtration System Maintenance

1. Regular Filter Replacement

A high-quality water filtration system is key to maintaining the efficiency of your commercial ice machine. Hard water can lead to scale buildup, which reduces efficiency and can damage the machine over time. Replace water filters every six months or more frequently in areas with hard water to ensure optimal performance.

2. Monitor for Scale Buildup

Even with a good filtration system, scale buildup can occur. Regularly inspect the machine for signs of scaling and take appropriate action. Descaling agents can help remove buildup, but ensure they are compatible with your machine to avoid damage.

Proper Installation and Environment

1. Adequate Airflow

Ensure your ice machine is installed in a location with adequate airflow. Overheating can cause the machine to work harder, reducing efficiency and lifespan. Keep the area around the ice machine clear of clutter and debris.

2. Optimal Temperature

Operating the machine in an environment within the manufacturer’s recommended temperature range is crucial. Extreme temperatures can lead to increased energy consumption and reduced ice production capacity.

Regular Inspections and Professional Maintenance

1. Visual Inspections

Perform regular visual inspections to check for any signs of wear and tear or potential issues. Look for water leaks, unusual noises, or changes in ice quality, which can indicate a need for maintenance or repairs.

2. Professional Servicing

In addition to your maintenance routine, have a professional technician service your machine annually. They can perform more thorough inspections deep cleanings, and identify issues that may not be visible during routine checks.

Ready to elevate the performance and efficiency of your commercial ice machine? At Airplus Refrigeration, Inc., we specialize in commercial ice machine rental, ice machine installation, and ice machine maintenance. Our team of ice machine specialists is dedicated to ensuring your equipment runs flawlessly, providing top-notch commercial refrigeration service in Los Angeles.

Learn more about our services.