Ice machines have become an indispensable part of our daily lives, particularly in the hospitality and food service industry. From chilling drinks to preserving food and ensuring medical supplies remain cold, ice machines play a crucial role. But have you ever wondered how these machines work their magic?

In this blog, we’ll explore the inner workings of ice machines to demystify their process.

The Ice-Making Process: Explained

Ice machines operate on a relatively straightforward principle: turning water into ice. This process typically involves three main components:

1. Evaporator

The evaporator is a crucial element in the ice-making process. It’s where the magic happens. Water is pumped into the evaporator, and a refrigeration cycle begins. A refrigerant, often a gas, circulates through the evaporator, absorbing heat and cooling the water.

2. Condenser

The condenser is responsible for releasing the absorbed heat back into the environment. As the refrigerant releases heat, it changes back into a gas, ready to repeat the cycle.

3. Compressor

The compressor is like the heart of the ice machine. It pumps the refrigerant through the evaporator and the condenser, facilitating the heat absorption and release process.

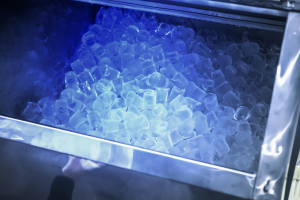

Ice Formation

As water flows over the evaporator’s cooling coils, it gradually freezes into ice. The design and temperature of the evaporator coils determine the type of ice produced, whether it’s cubed, flaked, or another variety.

Harvesting

Once the ice reaches the desired size and thickness, the ice machine initiates the harvesting process. This typically involves reversing the refrigeration cycle to warm the evaporator coils slightly, allowing the ice to release and drop into the storage bin.

Storage Bin

The storage bin is where the ice is collected and stored until it’s ready for use. It’s important to note that the storage bin should be well-insulated to prevent the ice from melting too quickly.

User Interface and Control

Most ice machines have user-friendly interfaces that allow operators to monitor the ice-making process, set the size and thickness of the ice, and schedule harvesting times. This control ensures that businesses can adjust ice production to meet their specific needs.

Ensure a Reliable Ice Supply with Ice Machine Rentals from Airplus Refrigeration

Understanding how ice machines work is essential for businesses that rely on them. If you’re in the food service, hospitality, or healthcare industry in Los Angeles, ensuring a consistent ice supply is vital for your operations.

Contact us today to learn more about our ice machine rental options, including Scotsman and Hoshizaki machines, and experience the advantages of having a reliable ice supply for your business. Whether you need to rent an ice machine for a restaurant, a hospital, or a supermarket, we have you covered. Our factory-authorized service agents can assist you with installation, refrigeration maintenance, and repair, ensuring your ice machine works at its best.